AI & ReMake!

What can it do

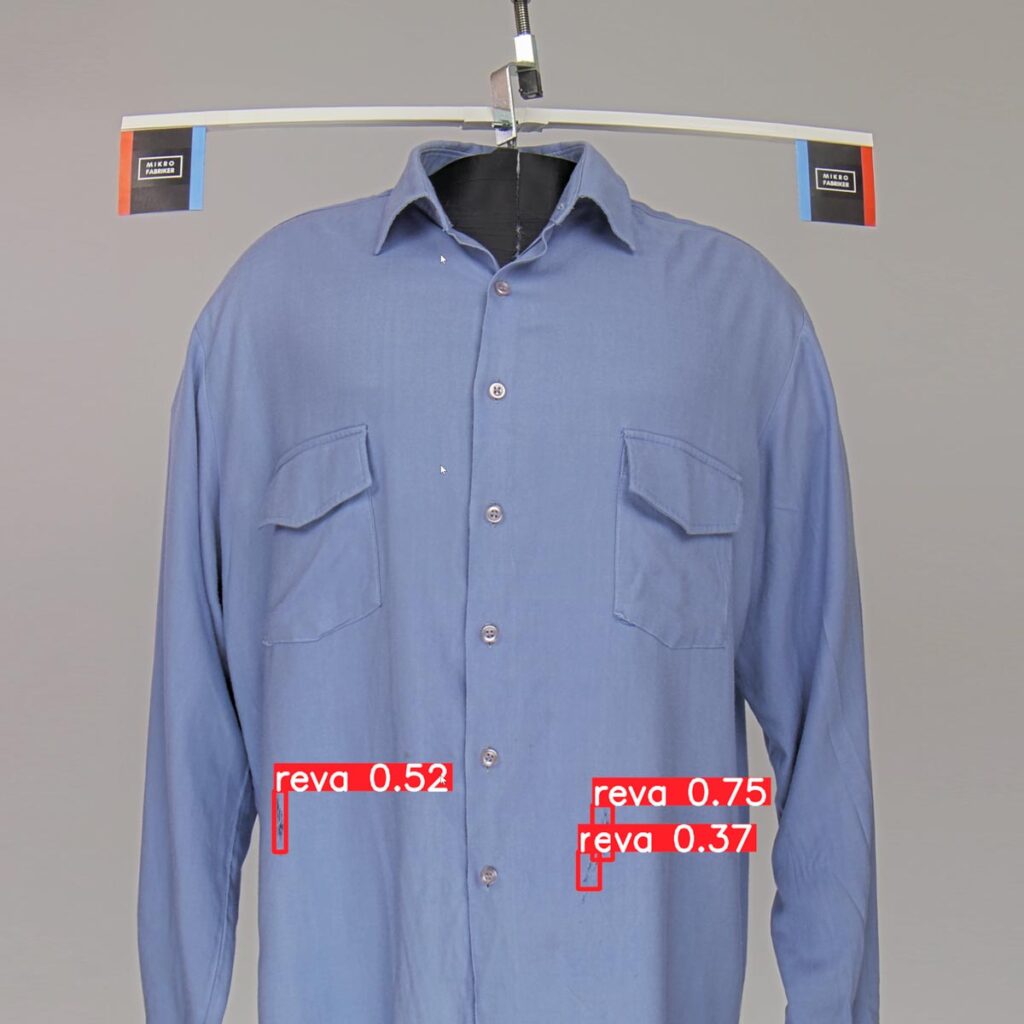

The project Microfactories has developed an automated flow for remake of garments that would otherwise be considered as waste. By using Eton Systems overhead conveyor system together with an AI that can detect defects and suggest design operations, the machine automatically adds value in form of design elements that repairs and covers up defects. This provides an opportunity for retailers to sell their products more than once and adding value to otherwise discarded clothing.

From small repairs

Unsellable items becomes sellable with repair

To reDesign

The factory

From bin - To hanger

Countdown to 2025

From Rules

Soon you will be responsible for the unwanted. Read more about the EU extended producer responsibility

To solutions

A large fraction of the clothing that will be collected could be resold through small design adjustments and additions and potentially attain a higher price than the original product. Not all garments should be recycled.

Let the AI sort it out

From Human touch

To Automation & AI

What can it do:

- Handling of the garments are done by Eton systems that can process unique items.

- Garments are automatically photographed for web shop publication in StyleShoots.

- Detection-AI: four stationary cameras and one mobile on a robotic arm,

- Detects defects such as holes, tears and stains.

- A suggestion of remake procedure generated by the design-AI.

- Eton systems automatically sends the garment to the correct work station.

- Remade garment published directly on web shop.

- Eton system sends garments to buffer.